Reservation booth:+86(0)21-3114 8748

Visit/media contact:+8613601815988

QQ:2463282767

email:artsexpo@sgexpo.cn

The Rail Transit Exhibition was informed that on April 15, in Xihanggang Street, Shuangliu District, Chengdu, in the Chengdu Rail Equipment Smart Factory, three rail transit vehicle maintenance robot "doctors" officially took up their posts to "inquire" about the vehicle door of Chengdu Rail Transit Line 10. Zhang Shihua, director of the technical center of Chengdu CRRC Rail Equipment Co., Ltd., introduced that this is the first time that the robot "doctor" has appeared in the rail transit vehicle maintenance industry in southwest China.

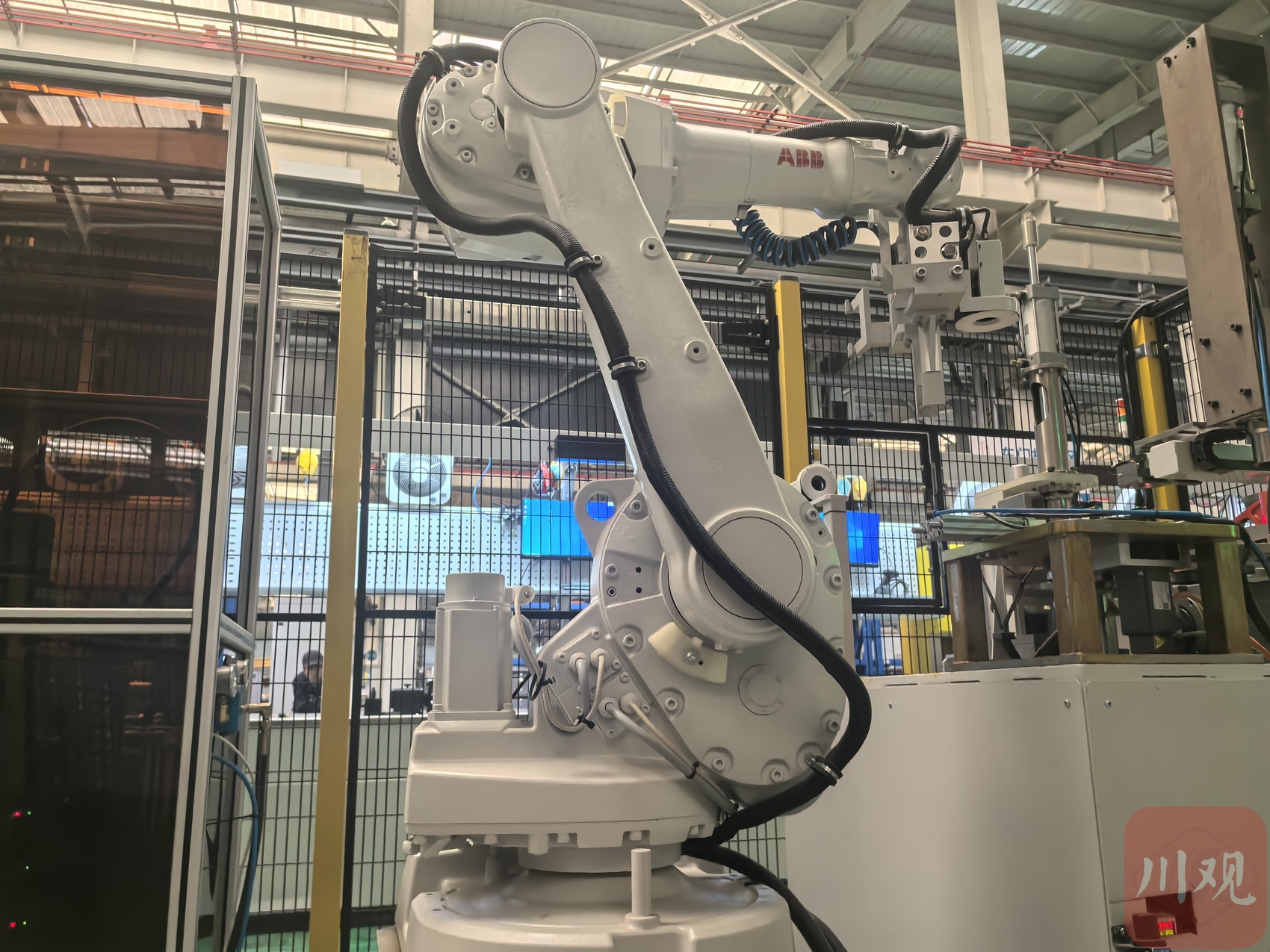

A robotic arm is overhauling parts of a vehicle door on Chengdu Metro Line 10. Photo by Duan Yuqing

According to reports, these robot "doctors" are part of the intelligent maintenance production line of the rail transit vehicle door system, and can be responsible for three types of doors: A-type, B-type subway and city trains.

On the side of the factory production line, the robotic arms of three robots are constantly rotating. The staff took out a gamepad-like manipulator, entered the corresponding instructions into it, and the robot began to work.

Quality engineer Madi is operating a robotic robotic arm. Photo by Duan Yuqing

On the computer screen next to it, there is an image recording panel of the robot, which is an electronic medical record of "one car and one gear". The launch of the robot "doctor" has also made it possible for vehicle maintenance to transform from "planned repair" of "regular physical examination" to "state repair" for precise treatment of pathology.

Quality engineer Madi is operating a robotic arm with a gamepad-like manipulator. Photo by Duan Yuqing

Speed and accuracy are also higher.

According to reports, the annual maintenance capacity of the intelligent maintenance production line of rail transit vehicle door system can reach 6,250 sets of doors. Compared with traditional manual maintenance, the assembly accuracy of key components of the robot's "consultation" can reach ±0.1mm, and the efficiency is also improved by about 100%.

The rail equipment smart factory is a rail transit vehicle maintenance base jointly built by Chengdu Rail Group, CRRC Sifang and CRRC Changqing, and has built 10 professional maintenance production lines including vehicles, bogies, gearboxes, air conditioners, etc. Zhang Shihua said that in the future, more robot "doctors" will be introduced to "maintain" and "treat" vehicles on more lines such as Chengdu Rail Transit Line 5, Line 6 and Line 10.