Reservation booth:+86(0)21-3114 8748

Visit/media contact:+8613601815988

QQ:2463282767

email:artsexpo@sgexpo.cn

Rail Transit Exhibition News Recently, at the construction site of Dongyue Road Station of Qingdao Metro Line 6 (hereinafter referred to as "Dongyue Road Station") of China Railway Fourth Bureau, the 25-meter-deep main structure floor was dismantled. This means that the concrete has hardened and stabilized sufficiently and meets the design requirements.

The reporter saw at the construction site that the surface of the outer wall of the station made of facing high-performance concrete was uniform, smooth and flat, and the open seams and cicada seams were regularly arranged. The exterior wall of the station seems to be covered with a natural and beautiful coat.

Facing high-performance concrete, which used to be used on above-ground building structures, was not an easy task to use in the underground Qingdao subway station.

Yang Yitao, chief engineer of Qingdao Metro Line 6 Project of China Railway Fourth Bureau, introduced that facing high-performance concrete has excellent mechanical properties, excellent durability, and can resist the erosion of various environmental factors such as salt and alkali, groundwater. "But in the process of construction and use, there are often times when the facing high-performance concrete is 'angry'." Yang Yitao said that this kind of concrete is prone to problems such as poor appearance quality, cracks, and water seepage, which affects the overall appearance and durability of subway stations.

In order to solve the above problems, the technical staff of the Dongyue Road Station Project Department continuously optimized the construction plan, strictly controlled the quality of concrete raw materials, accurately proportioned the concrete mixture, and carried out multiple construction parameter tests. According to the test results, they screened out the optimal construction parameters for the spacing between the concrete vibration and the distribution holes, and used stainless steel cladding formwork to ensure the gloss and flatness of the concrete surface. Not only that, in the actual construction process, the technicians also eliminated the cracks caused by bubbles and temperature differences, so that the finished concrete color is consistent and the surface is smooth, so that the concrete surface presents a mirror-like effect.

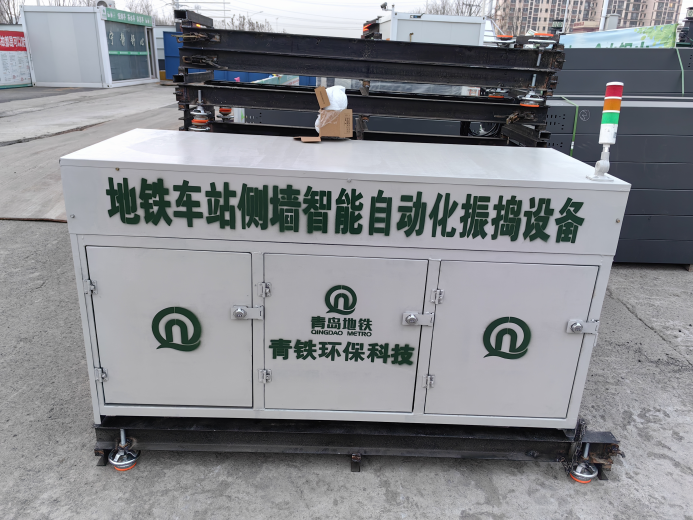

In addition, the facing high-performance concrete is also relatively "squeamish". Its stability is susceptible to factors such as the number of vibrations and the ambient temperature. "To this end, we have introduced advanced technologies such as cooling and cooling systems, intelligent constant temperature maintenance equipment and automatic vibration equipment." Yang Yitao said.

He introduced that the cooling and cooling system can effectively reduce the peak temperature during the heat of hydration of concrete and reduce the occurrence of harmful cracks. The intelligent constant temperature curing equipment adopts the "five-degree joint control curing mechanism", which can put on adaptive and self-adjusting "new clothes" for the concrete, ensure the constant temperature and humidity of the concrete surface, ensure the normal development of the concrete during the curing period, and reduce the temperature difference cracks and dry shrinkage cracks; Automatic vibrating equipment can improve the efficiency and quality of vibrating and ensure the quality of construction.

Wang Kaifang, the project manager, said that at present, the construction technology of facing high-performance concrete has been fully promoted in the third phase of the construction planning project of Qingdao urban rail transit.

"This process effectively reduces the need for decoration and grouting to plug leaks, and achieves the purpose of saving resources, saving energy and environmental protection." Wang Kaifa said.