Urban rail transit based on big data

Operate a comprehensive production control platform

Tianjin Rail Transit Operation Group Co., LtdAbstract:In the context of the digital transformation of the urban rail industry, this paper combines many years of experience in comprehensive management of urban rail operation and production, and elaborates in detail on the design, implementation, scenario application and implementation effect of big data technology in this field. In the era of big data and AI, data has become a new resource and production factor, and when the explosive growth of data encounters unprecedented computing power and connectivity, the "fusion" effect caused by it is comprehensively driving the transformation of the digital model and advancing in the direction of deep integration of digital and business. Focusing on the basic concept and methodology of enterprise digital transformation, this project has built a comprehensive management and control platform with operation and production management business as the core and data-driven, covering all fields of operation and production management, promoting the interconnection of everything, strengthening new digital innovation capabilities, forming a digital ecology of production control and control, and completing the value system reconstruction of digital transformation.Key words: big data driven; comprehensive control; digital innovation;1 Construction backgroundWith the continuous expansion of the network scale of rail transit operation and production, the operation and production management model is becoming more and more complex, the pressure of operation and production management has risen sharply, and the pain points and difficulties of urban rail production management business have become more and more prominent. First, the degree of data resource sharing between various systems is low, and the efficiency of business integration and work collaboration is insufficient. Second, the data is not credible, available, manageable and timely, resulting in the inability to fully exert the value of the data. Third, the refined control of the complete production business flow is insufficient, which cannot meet the production management business demands of "safety, efficiency, comprehensiveness and quality". Fourth, it is impossible to use data as an incision to dig deep into the value of data, and drive business based on data to solve the difficulties and pain points in production management business.In order to implement the development goal of "transportation power", implement the "Outline for the Development of China's Urban Rail Transit Smart Urban Rail", "Action Plan for the Development of China's Urban Rail Transit Green Urban Rail" and other relevant action deployments. In the "Three-Year Action Plan for the Informatization of the Operation Group" released in 2021, Tianjin Rail Operation Group Co., Ltd. proposed the strategic deployment of digital transformation based on the construction of a comprehensive management and control platform for urban rail transit operation and production driven by big data.2 Information construction goals

In order to further promote the digital transformation process of enterprises, break information islands, and tap the value of data, Tianjin Rail Transit Operation Group Co., Ltd. has built a high-precision and high-availability operation and production control platform with multi-section data interconnection and covering the whole operation and production based on years of production management experience, with production business as the main line, data-driven, digitalization, networking, and intelligence as the means, relying on cloud platform and data sharing platform. Realize the digital management and control of the whole life cycle operation and production business, achieve the purpose of improving the initiative of production control, expanding the scope of management efficiency, promoting the improvement of production management level, and reducing the investment in human, financial and material costs, and achieve the construction goal of refined operation and production and digital management.

3 Information construction planning

The construction plan of the operation and production integrated management and control platform is based on the digital transformation methodology combined with the actual business situation of production management, and is implemented in the following three steps: current situation analysis, architecture design, and clear implementation path.

Fig.1 Steps of informatization construction planning3.1 Analysis of the current situationThe first is to clarify the current status of existing IT resources, such as computing, storage, network, security, data, technology, and support platforms, according to the information system access standard system. The second is to clarify the digital vision of production business, and combine the current technology trends such as cloud computing, big data, Internet of Things, blockchain, 5G, and AI to appropriately identify the entry points of key business scenarios and solve the difficulties and pain points in the existing production management field. The third is to sort out the production business flow and data flow, and through detailed research and discussion, combined with the production management business to sort out and integrate the data and business level to form an overall strategic project construction plan.Through detailed demand research, clarify the digital vision and goals of comprehensive management and control of operation and production, review the resources of each link of the support system, and improve the value flow, data flow and business flow formed by the current situation analysis link. Based on big data, business trends, and new technology support, the design and drawing of system architecture is carried out from the levels of system function, business model, system establishment, data model, platform support, data support, and service support to support the realization of the overall digital scenario of the project.

Figure 2 Architecture design diagram of the integrated management and control platform for operation and production3.3 Clarify the implementation pathBased on the architecture design and digital key measures of the operation and production comprehensive management and control platform, the overall implementation strategy, project plan list, and project detail and decomposition are formulated, and finally the overall project planning list based on the group's overall strategy is realized.

4 Information product selection

In 2021, Tianjin Metro completed the construction plan of the project, and carried out in-depth exchanges and inspections against the intelligent construction and digital transformation application cases of similar industries at home and abroad in terms of operation and production control. In the process, experts in related fields such as design institutes and software research institutions were invited to participate in the discussion. After investigation and analysis, there is no mature set of software products in the rail transit industry, Tianjin Metro decided to take the customized R&D route, carry out digital and intelligent construction exploration, closely follow the main line of "smart urban rail, green and intelligent integration", and adhere to the construction concept of unified design, overall planning and distribution implementation in view of the many problems highlighted by the comprehensive control of Tianjin Metro's operation and production, and make full use of existing IT resources and advanced IT technology means to analyze, evaluate and reorganize the existing big data platform. Integrate massive multi-source heterogeneous data and dynamically derived data to achieve the overall design vision of "business-centered, platform-supported, and data-driven".5 The implementation process of informatization and the content of the application system

5.1 Data aggregation: break the isolated "chimney", realize data-driven business, and weaken the manual operation links in all aspects of operation and production

Data aggregation is the implementation or regular batch aggregation of data (including structured, semi-structured and unstructured data) scattered into various application subsystems to form the source data of the big data platform. On this basis, this project highlights the main line of Tianjin Metro operation and production management business as the core, connects personnel, organization, contract, budget, cost, construction, equipment maintenance, materials, procurement, risk control, indicators and other derivative data, standardizes the production business process with data, and establishes a network of urban rail information operation production management system. Relying on the big data platform, data-driven operation and production are integrated into a whole, weakening the manual operation links of each business node, realizing the interconnection of production data, integrating data resources, tapping production potential, and implementing digital control of the whole life cycle of operation and production business.5.2 Data governance: Make data trustworthy, available, and manageable

Data governance is related to data quality, which affects the effectiveness of digitalization of comprehensive management and control business in operation and production. In order to ensure the authenticity, timeliness and effectiveness of data, data governance has become a key task after data aggregation: First, relying on the data sharing platform, sorting out the data asset catalog, clarifying the flow trend of each business, managing massive data, the same data, and multi-level data through data graphization, and clarifying the data context. The second is to establish a data quality monitoring platform to realize the full life cycle management of data, ensure the accuracy, availability and security of data, and achieve pre-event security policies, in-process data flow control, and post-event data audit and analysis. The third is to establish data standards, set up management standards, business standards, and technical standards, and unify the four levels of name, definition, rule, and standard, so as to realize the standard creation, standard management and mapping management of data, and ensure the standardization of data.

5.3 Data convergence: Closely integrate data and business

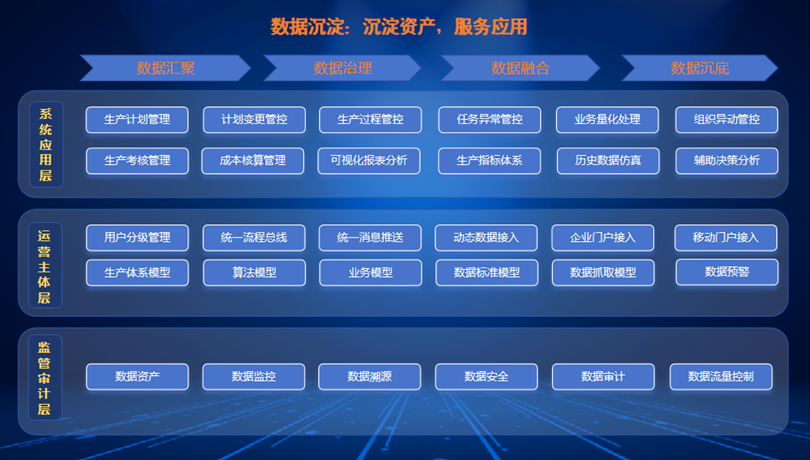

Figure 3 Data fusion diagramAfter the standardized operation of data governance, based on the business links of Tianjin Metro operation and production management, six data models of production planning, production control, production indicators, cost accounting, production assessment, and auxiliary decision-making have been established. According to the characteristics of each business, system construction and data modeling are carried out, production tasks are quantified, business is measurable, production progress can be controlled, and the business value of data processing is ensured, which is conducive to shielding the impact of business changes in production management, shielding the anomalies of original data, and making the data structure clearer, more transparent, and conducive to data traceability.5.4 Data precipitation: precipitate assets and serve applicationsMaking the precipitated data serve the application is the result of data aggregation, data governance, and data fusion, and it is the true combination of data and business. After data precipitation, it can not only be used internally in the enterprise, but also developed by third parties to connect upstream and downstream users to form a data ecosystem. The project divides the top-level application of the system into supervision and audit layer, operation entity layer and system application layer to provide services to different users through the flexible service capabilities provided after data precipitation.

Fig.4 Data precipitation diagram6 The effectiveness of information system construction

The establishment of the Tianjin urban rail operation and production comprehensive management and control platform is a specific first in the urban rail industry, with the characteristics of agile response, multi-source integration, and general expansion, which gives greater value to the construction of complex and changeable line-network level operation and production control business. Relying on existing basic resources such as data sharing platforms, cloud services, and IT services, it has built operation and production management and control services for users at different levels, promoting efficient collaboration of multiple data and services with operation and production as the main line. The project was put into use in October 2022 and has complete independent intellectual property rights, and its construction results can be widely promoted and applied in rail transit and related production industries.6.1 Big data driven: help the innovative practice of production control business

The application of big data is the basis of the system, through data aggregation, data governance, data precipitation, data fusion, data precipitation and other technical means, the high degree of integration and rapid response of data in various operation and production business fields is realized, while reducing the difficulty of production control and greatly improving the efficiency of operation and management production.At the same time, the implementation of the project provides an intelligent and visual bearing platform for multi-source production data, which can penetrate the overall picture of Tianjin urban rail operation and production, and can carry out intelligent production simulation and prediction based on big data, and comprehensively present the data indicators of each production-related business section, so that the overall situation of operation and production is digitized, three-dimensional and dynamic, and the collaborative linkage and refined management of operation and production business can be realized.6.2 Digital empowerment: digitalization of the whole life cycle of production management

The implementation of the operation and production control platform project covers the business, process and data in the field of the whole operation and production, breaks through the data barriers between personnel, organization, budget, contract, cost, construction, maintenance, equipment, materials, procurement, risk control and other businesses, realizes the comprehensive production and operation management of all elements, all scenarios and the whole process, explores and verifies the innovative production management model, starts from the digital management of the whole life cycle, mines the maximum value of data, and enhances the controllability of operation and production. It ensures the sustainable development of operation and production, and creates a benchmark for digital transformation in the field of comprehensive management of urban rail operation and production.6.3 Smart Exploration: Entering the "Fast Road" of Data

The digitalization and intelligence of operation and production management are highly in line with the "1811" layout of the "China Urban Rail Transit Smart Urban Rail Development Outline", and provide a digital intelligence base foundation for the construction of various intelligent scenarios by building business models, system models, and data models, so that various services can be perceived, predicted, and linked, and promote the comprehensive improvement of production, control, safety, efficiency, and experience.6.4 Reduce costs and increase efficiency: comprehensively improve the economic and social benefits of operation and production

The digital innovation of the operation and production management mechanism has realized the efficient collaboration of various business sections, driven the business with data, streamlined the process, improved the transparency of the management process and production process, reduced management costs, and greatly improved work efficiency. Relying on the big data platform, the timeliness, authenticity, validity and traceability of the dynamic data of each link are ensured, and the coordinated development of safety production and business development is realized.With the implementation and application of the system in Tianjin rail transit operation, the configuration and optimization of various indicators and production costs of conventional equipment and facilities of each specialized subsidiary can be optimized, and according to the company's operation support needs, make full use of the cost reduction space, strategically arrange key production projects, promote the control of operating production costs, and achieve "cost reduction and efficiency increase". Since the implementation of the system, it has saved more than 1,000 yuan in costs and produced certain economic benefits.With the gradual implementation of the system, from 2021 to 2022, the annual planned initiation rate of each production unit will be 100%, and the production completion rate will be higher than the company's annual 94% target requirement for two consecutive years, reaching a maximum of 97.43%, and the overall plan completion rate will increase by about 7.77% compared with before the system application and promotion. In addition, the supporting cost of conventional standardized production decreased by about 17.8 million yuan year-on-year, and the production organization arrangement tended to be more intelligent, scientific and reasonable, which has certain social value in serving the smooth travel of the people by subway, the reform of state-owned enterprises and the cost reduction and efficiency increase of the urban rail industry.

7 Summary of experience in information construction

7.1 Use digital technology to achieve the vision and goal of operation and production control

Realizing integrated operation and production comprehensive management and control actually solves the problems of data coordination, governance, integration, precipitation and interconnection of operation and production systems. Relying on intelligent and digital technical means, we can break the "barriers" of the traditional operation and production management system, enhance the internal and external connection of upstream and downstream data, and integrate data and business into a whole. Therefore, the successful implementation of the project requires fully considering the rational use of existing IT resources and data resources in the planning stage, sorting out and reconstructing, and planning the digital transformation of the organization, business, and data through top-level design, forming a vision map, planning blueprint, architecture design drawing, project implementation and deployment, and finally forming the successful implementation of the project.7.2 Implement construction and pay close attention to the focus of digital transformation

In the process of project implementation, the use of new technologies has become a key step in the whole process, life and cycle of digital empowerment, ensuring the smooth implementation of the planning blueprint in the construction and implementation process. Digital empowerment construction can realize the effective connection between data and business, and ensure the top-down implementation of the project. Faced with complex problems such as complex construction scenarios, massive data access, and many business processes, it is necessary to take the governance of master data as the starting point, grasp the focus of digital transformation, rationally plan various resources, empower construction with digital, comprehensively control the comprehensive overview, investment, progress, safety, quality, personnel, equipment and other information of project construction, and follow the model of "undertaking planning and construction, starting digital construction below" to achieve rapid project landing.

Rail Transit Exhibition booth reservation

Free registration for the rail transit exhibition