Reservation booth:+86(0)21-3114 8748

Visit/media contact:+8613601815988

QQ:2463282767

email:artsexpo@sgexpo.cn

On August 20, 2024, Harbin Metro Group organized CCCC First Harbor Bureau to conduct a comprehensive "physical examination" of the two "C" type contact channels between the Northwest Semi-Ring Road Bridge Station of Metro Line 3 Phase II ~ Hesong Street Station and Hesong Street Station - Heshan Street Station, and all indicators met the design and specification requirements, which marked the successful solution of the technical problems of the first "C" type contact channel of the stacked interval freezing method in Northeast China.

The second phase of Harbin Metro Line 3, as the backbone of the urban rail transit network, is extremely challenging in design and construction. Among them, the highway bridge station ~ Hesong Street station ~ Heshan Street station is located under the Qianjin Road viaduct for two consecutive sections, near the existing buildings, the surrounding environment is complex, if the parallel section needs to pass a large number of buildings and bridge piles, the construction risk and difficulty are extremely great, so the upper and lower stacking arrangement is adopted. Therefore, the connecting channel of these two sections needs to be designed as a stacked "C" type connecting channel that is also stacked on top of each other.

This form of communication channel is rare in China, and it is the first case in Northeast China. Due to the narrowness of the surrounding construction site and the difficulty of traffic organization, it is impossible to carry out open-cut construction operations, so the Metro Group and CCCC First Harbor Bureau organized relevant experts to combine the geological conditions of Harbin and the on-site implementation conditions to determine the process of freezing and underground excavation in the contact channel. And innovatively proposed to adopt the four-stage excavation form of full-section freezing, to overcome many difficulties such as complex freezing form, large freezing volume, long freezing time, and many frozen hole layouts, and successfully completed the construction of two C-type contact channels.

First, the structure type is complex, and the construction process is changeable

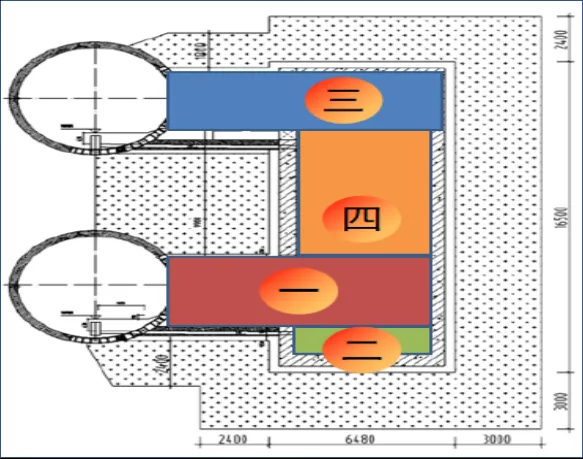

The conventional parallel tunnel connecting passage adopts a "one" shaped design, and the construction is relatively simple, usually only more than ten meters of horizontal passage is opened. However, the "C" type connecting channel in the stacked section is much more complex, with a structure of stacked up and down, and the construction needs to be carried out in four stages. First of all, it is necessary to construct the transverse passage part of the lower tunnel connection, then construct the foundation and the pump room part at the bottom of the connecting channel, then construct the transverse passage part that is connected with the upper tunnel, and finally complete the vertical connection of the upper and lower passages. This kind of structural form is relatively rare in the whole country, and there is no precedent in similar strata in Northeast China, which poses a serious challenge to Harbin Metro Group and CCCC First Harbor Bureau.

In order to ensure the smooth progress of the construction, the engineering team conducted a detailed study of the operation process, construction schedule and risk control of each process. The metro group will carry out conditional acceptance before each operation to ensure that the site is fully prepared before carrying out the next step of construction.

Compared with the 130-day construction period of the conventional contact channel, of which the freezing time is about 70 days, the construction process of the "C" type contact channel is significantly complex. The amount of excavation is about 1,200 cubic meters, which is four times that of the conventional design, and the total construction period is about 300 days, the freezing time of the lower layer is 200 days, and the freezing time of the upper layer is 175 days, which is three times the duration of conventional freezing.

(Schematic diagram of C-type connecting channel structure)

Second, the project time is long and difficult, and the frozen volume is unprecedented

Faced with the problem of large volume of frozen wall and difficult risk control, the project team of CCCC First Harbor Bureau, the construction unit, adopted an advanced method of combining vertical junction on the ground and horizontal freezing in the cave to ensure the stability of the soil. Among them, the thickness of the frozen wall of the floor of the vertical section is 4m, the thickness of the frozen wall of other parts is 3m, and the frozen volume is about 5000m³, which is about 7 times that of the conventional contact channel. The length of the frozen pipeline is 4,736 meters, which is 5-7 times that of the conventional contact channel. Due to the large freezing volume, the scope and impact of thawing settlement will also increase accordingly, so it is necessary to closely observe the ground subsidence during the thawing period, and start the thawing and sedimentation grouting in time to ensure the stability of the ground and surrounding buildings. The freeze-thaw grouting time of the two connecting channels is as long as 6-7 months after the completion of the structure.

3. Overcome construction problems and explore scientific and technological research and development

In order to cope with the complex geological conditions of the water-rich sand layer in the alpine region, the Harbin Metro builders successfully overcame the technical problems of the freezing construction of the "C" type contact channel with excellent technology and innovative spirit. Metro Group and CCCC First Harbor Bureau have set up a technical research team to carry out research on key technologies in the construction of the freezing method of water-rich sand layer stacking contact channel: in view of the characteristics of large frozen volume and fast development of frozen wall, the waterproof effect and strength of the frozen wall are fully considered, and the zonal phased freezing scheme is implemented; The intermittent freezing control technology is adopted to avoid the formation uplift caused by the excessive volume of the frozen wall. The force monitoring of the primary support and secondary lining structures was carried out, and the stress after freezing excavation and structural forming was analyzed, so as to provide a reliable basis for the structural safety judgment. Using the extremely cold environment of Harbin in winter to cool down the salt water, the applicable freezing hole layout spacing and layout method were studied, which effectively saved the energy efficiency and economic cost of refrigeration, and formed a set of natural cooling utilization technology, which provided a reference for freezing construction in severe cold areas, and was also an important attempt to lead the progress of the industry and achieve the goal of carbon peaking and carbon neutrality.

Through innovation to overcome difficulties, Harbin subway builders continue to sum up lessons and lessons, and form a set of water-rich sand layer stacked section of the "C" type contact channel freezing construction method in the alpine region, which not only shows China's profound strength in the field of rail transit construction, but also marks a solid step forward in China's subway construction technology in the alpine region, and realizes the catch-up and transcendence of the domestic advanced level.

Fourth, practice the mission of state-owned enterprises and assume social responsibility

The two overlapping sections of the second phase of Harbin Metro Line 3 are close to the viaduct, and there are many old buildings around it, narrow roads and large traffic flows. If the open-cut method is adopted, it will produce a large construction enclosure and noise pollution, which will have a serious impact on the living and travel, road traffic, and shop business of the surrounding residents.

Although the underground excavation project is difficult and risky, the subway builders have overcome many difficulties such as complex freezing form, large freezing volume, long freezing period, large amount of melting and sedimentation grouting, strict deformation control, and complex construction structure, and effectively solved the problems of underground pipeline relocation, road occupation, tree transplantation, shop closure, noise disturbance, etc., greatly reducing the risk of building deformation, and at the same time, it can organize construction operations without being affected by seasonal changes, effectively saving the construction period, and completing the construction task 16 days ahead of schedule.

The implementation of the construction method of the project provides a new idea for the subway construction in the water-rich areas of the severe cold zone in Northeast China, and has handed in a satisfactory answer to the citizens of Harbin. This is not only the firm commitment of the subway builders to minimize the social impact and maximize the interests of the people, but also reflects the service concept of the subway group of "giving convenience to the citizens and leaving the difficulties to themselves", as well as the state-owned enterprise style of not being afraid of difficulties, having the courage to take responsibility, and being the guardian of people's livelihood and well-being.

Rail Transit Exhibition Booth Reservation

Rail Transit Exhibition Free registration for visit